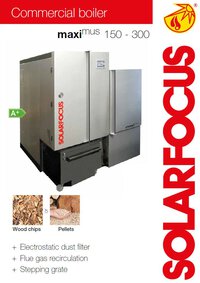

maximus -

Commercial boiler up to 300 kW

INNOVATIVE: Feed grate + integrated electrostatic particle filter

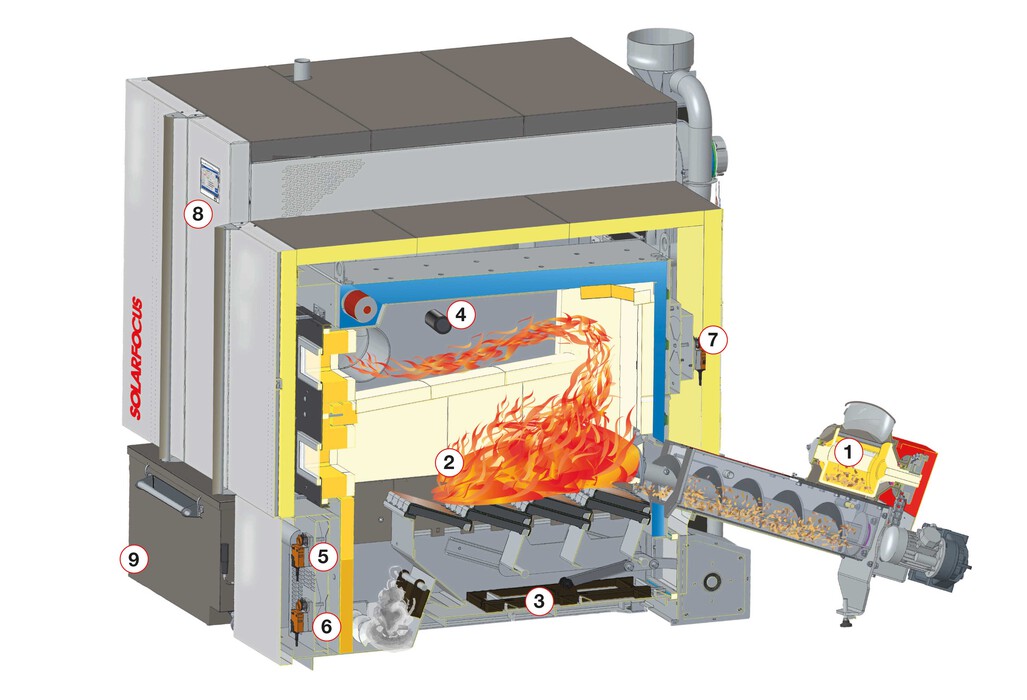

The maximus boiler is a result of distinguished innovation. A reciprocate moving step grate ensures the seamless firing of the fuel conveyed into the combustion chamber. This enables the boiler to process a wide range of fuels, such as pellets or wood chips, with outstanding efficiency and low emissions. Combustion chamber temperature monitoring and integrated flue gas recirculation ensure a steady combustion of fuel materials of varying qualities while preserving the boiler’s service life.

-

Industrial moving grate

-

Exhaust gas recirculation integrated as standard

-

Integrated electrostatic particle filter for lowest dust emissions

-

For wood chips P16S-P31S (G30 - G50) , max. 40% water content

Available power sizes:

- Wood chip: 149 kW / 201 kW / 249 kW

- Wood pellet: 149 kW / 20 1kW / 249 kW / 299 kW

- In cascade up to 1.8 MW

Selecting the right heating boiler is an important decision that will have an impact for many years. The pellet and wood chip boiler maximus generates heat for applications requiring a medium to high output. The maximus is an optimum solution for commercial sites, for the construction of apartment buildings and for applications requiring a high level of operational reliability. When installed in a cascade configuration (consisting of a number of boilers), the maximus can deliver a maximum output of up to 1.8 MW.

An electrostatic dust filter is used to clean the exhaust gases to get particle-emissions to a minimum. The filter is automatically cleaned in regular intervals. Both technologies come as standard equipment. The ID fan with EC motor and a lambda sensor ensure an efficient and clean combustion at both full and partial load operations.

The large 7’’ ecomanager-touch control unit combines all boiler control functions in one convenient user interface. The controls can also be mirrored on a smartphone, PC and tablet computer using a VNC server or a smartphone app.

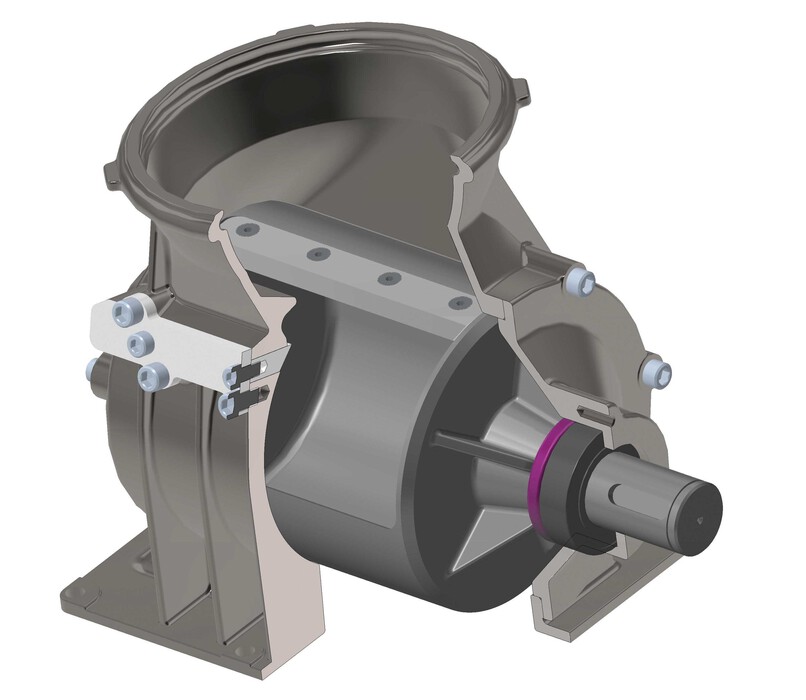

Rotary valve with plug-in unit

The rotary valve offers maximum protection against burn-back for all kinds of fuels. The generous single

chamber design means that only fuel pieces material of excess lengths will have to be cut. This results

in exceptionally low wear and tear and an extended service life. The hardened blades can also be exchanged

if necessary.

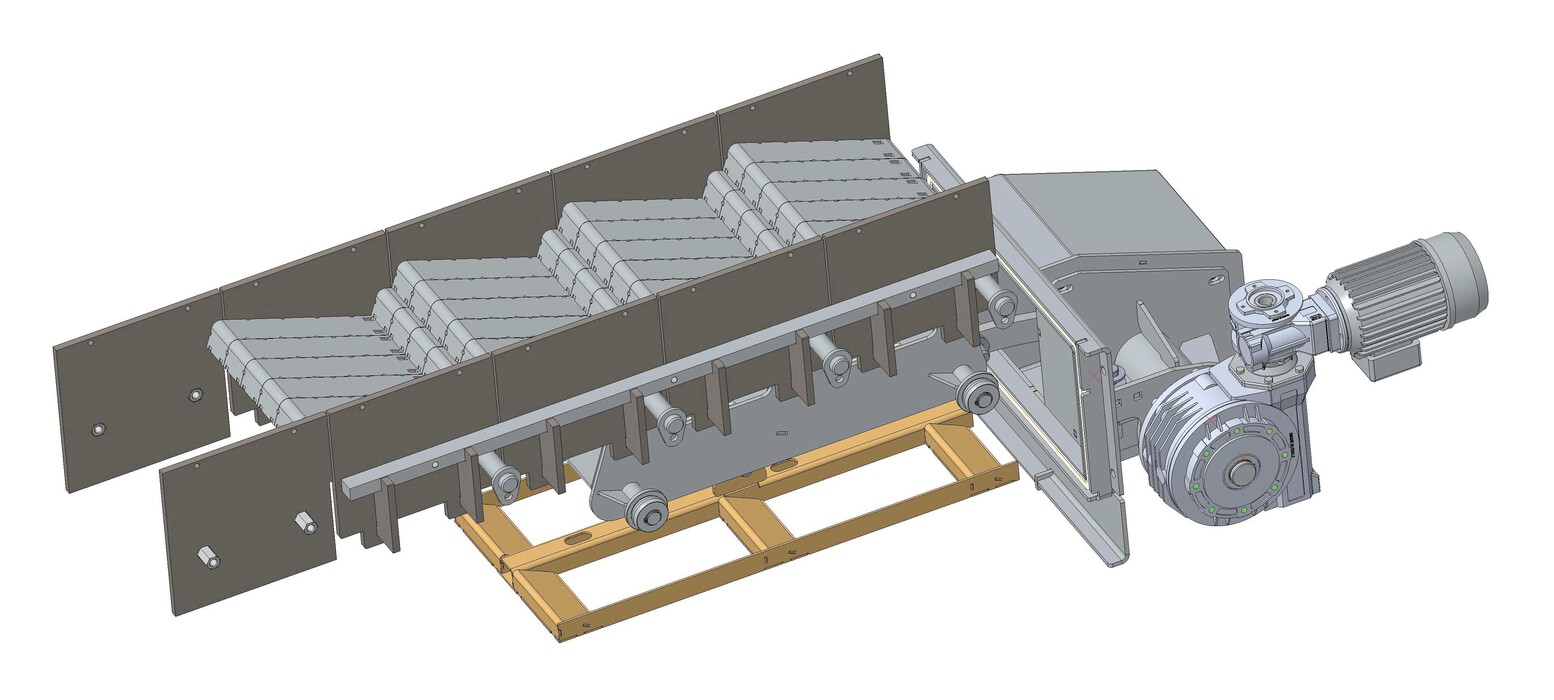

Combustion chamber with reciprocate moving step grate and ash scraper

High temperature-resistant combustion chamber with reciprocate moving step grate. The step grate moves at variable speeds depending on the required force and ensures the clean combustion of more difficult materials, which in turn prevents the formation of slag and ensures operational reliability.

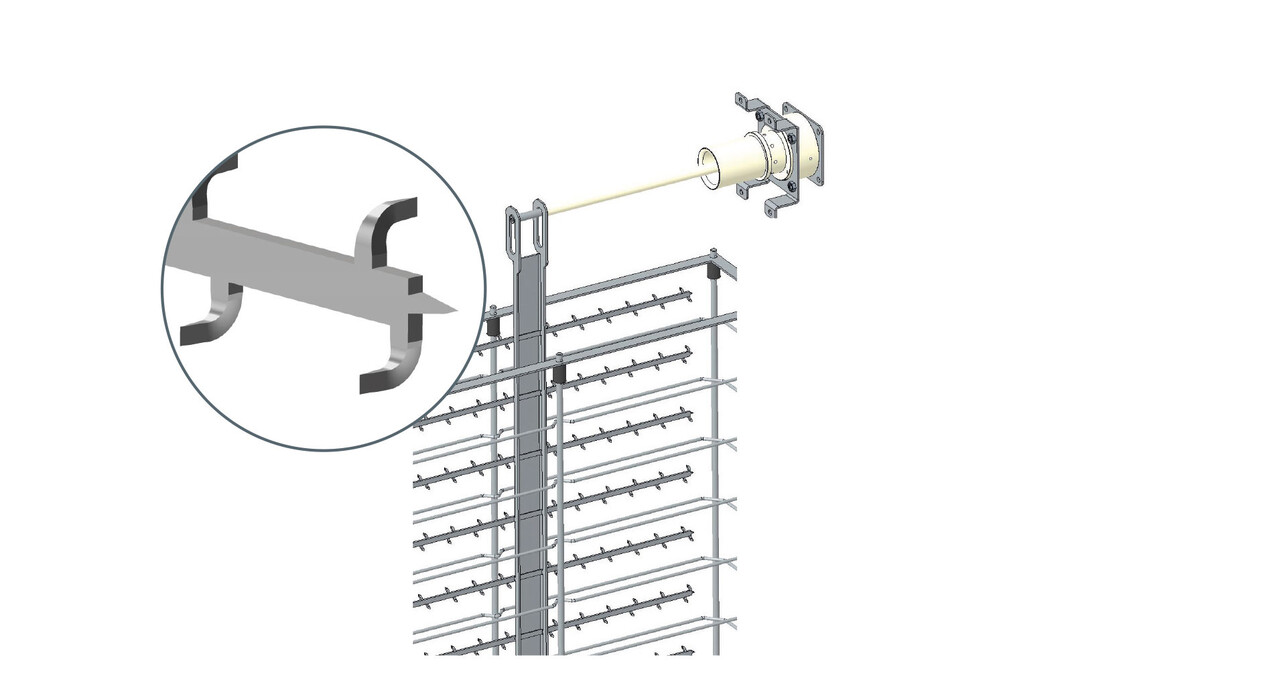

Electrostatic dust collector

To filter even the last remaining dust particles from the flue gas stream, SOLARFOCUS has developed an integrated electrostatic dust collector that comes as standard equipment. An electrode ionises the tiny dust particles, which then form a layer of dust deposits around the electrode. The electrode is cleaned automatically during the course of the heat exchanger cleaning process. External cleaning facilities that frequently incur additional costs are no longer required.

Caption:

-

Feeder with rotary valve

-

High temperature-resistant combustion chamber with reciprocate moving step grate.

-

Ash scraper

-

Combustion chamber temperature monitoring

-

Recirculation control

-

Primary air control

-

Secondary air control

-

Controller ecomanager-touch

-

Ash box

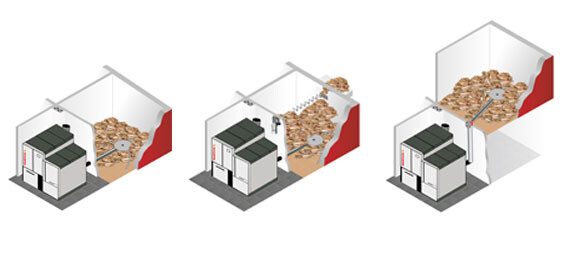

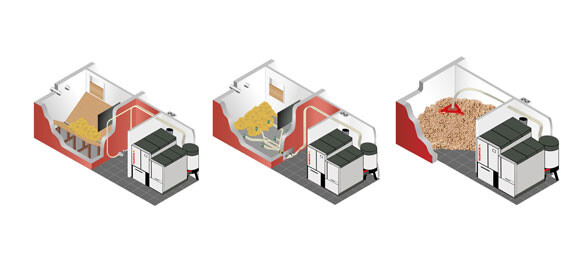

Wood Chip extraction

Our wood chip extraction systems are available with different screw lengths and as well with different agitator diameters. The agitators are available up to a diameter of 6m. Depending on your local situation the best option on screws will be chosen.